Looking at a golden-brown bar of Aleppo soap, inhaling its earthy scent, I see desert, stone landscapes, olive groves covered with dust, hot earth, the sun, ancient buildings. Then all the memories and stories I have experienced from my trips to Syria appear.

I went there mainly to discover the secret of Aleppo soap. I wanted to learn about the production process, its history and find out what is the difference in the quality of Aleppo soaps offered at every bazaar, in shops, at street stands. My husband and I visited the most respected soap houses in Aleppo, asking about the details and history of soap. In each of these places, their soap was considered to be the best.

Aleppo soap called Syrian soap, laurel soap or in Arabic Ghar soap. It is considered the green gold of Syria. It is the oldest soap in the world, with a tradition dating back several thousand years.

Traditional Aleppo soap has been made in the same way for several thousand years

way – olive oil, bay berry oil, sea water and the saponifying substance, i.e. lye (originally in the old days

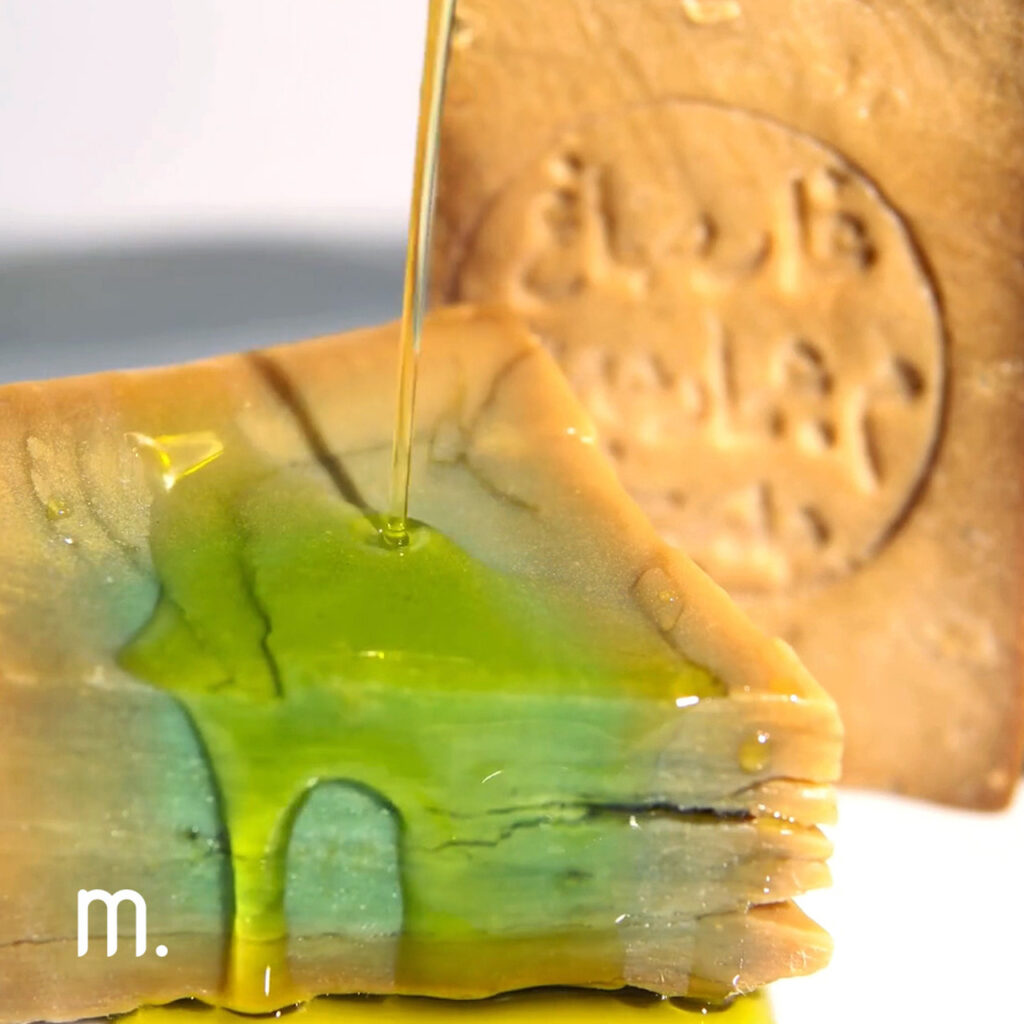

ash from hard varieties of trees was used instead of lye). The traditional Aleppo soap is made by boiling olive oil, seawater and lye in large vats for 2 or 3 days. When the mass thickens, the bay berry oil is finally added, which is the key to this recipe. The next day, the soap mass is poured into a large mold, which is placed on the floor and lined with wax paper. The mass is a vivid emerald green color and forms flat over a large area. This way it cools down and hardens, and during this time it is smoothed and leveled with wooden boards tied to the feet. The next day, it is diced with a special device that looks like a rake. Then each cube is hand-stamped.

Finally, the soaps are stacked alternately in high towers so that by each ankle had air circulation (access). When it dries up it is laid out in a cooler place so that it matures for 6-12 months. The maturation of the soap is important as it then takes on its own delicate qualities, its humidity is reduced, it becomes tough and permanently. During this time, it changes its color – it becomes golden brown on the outside, inside it remains dark green. It is a really lovely color combination. Soap is believed to get even better over time and can be kept for years.

Production seems simple, the number of ingredients is small. However, don’t let this be confusing – the manufacturing process is a craftsmanship skills that soap makers learn from their young age, from their fathers and grandparents from generation to generation. Because the details are the most important imitation of Aleppo soap by soap makers from the west, according to his “simple recipe”, turns out to be very problematic.

The production season begins immediately after the olives are harvested are collected from the end of November and lasts until the end of March / April. Local villagers harvest olives grown massively throughout the province Aleppo and bay berries that grow wild in the forests of northern Syria.

Unfortunately, the historic Aleppo soap factories were destroyed in during hostilities, but the masters of soap making continued manufacturing of Aleppo soaps in factories established in Lebanon, Tunisia, Turkey or France.

Aleppo Mohani Soap is made of Olive Oil and Laurel Oil. It is completely natural, does not contain any synthetic ingredients or other additives. It is biodegradable. Aleppo soap is one of the best bar soaps for sensitive skin. Its benefits have been appreciated for centuries, and today it is appreciated by dermatologists and doctors around the world.

While traveling in Syria, I collected various types of Aleppo soaps, in the end I had a whole suitcase [...]

Looking at a golden-brown bar of Aleppo soap, inhaling its earthy scent, I see desert, stone landscapes, [...]

For Aleppo soap in the footsteps of former Silk Road merchants. In my long-term search for natural [...]

The skin of our lips is thin and delicate. Due to the lack of melanin and a very small amount of [...]